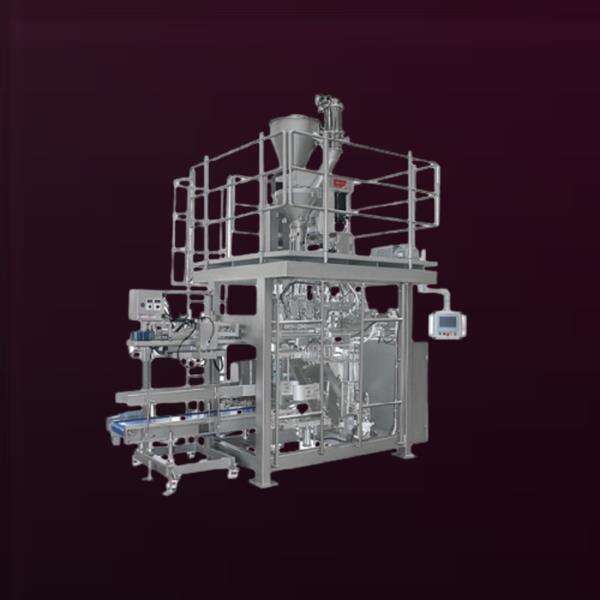

Automatic Bag Stitching Machine by JCN: The Ultimate Solution for your packing needs.

Have you been packaging that are fighting quantities of items? Do you wish to automate your packaging procedure? Then an automatic bag stitching machine is the solution, as well as the JCN's powder sifter machine. We are going to explore advantages, innovation, security, use, how to use, service, quality, and application regarding the automated case stitching machine.

An Automatic Bag Stitching Machine has several advantages within the conventional stitching process that are handbook, the same as salt packing machine manufactured by JCN. It could stitch bags of various sizes and thicknesses, rendering it versatile for the range that are wide of needs. Furthermore, it can stitch bags at high speeds, which increases efficiency and reduces work expenses.

The Automatic Bag Stitching Machine is an machine that has revolutionized the packaging industry, identical to JCN's product automated baggers. It is designed with higher level technology which allows it to detect faults into the stitching procedure, such as thread breakage and missed stitches. This helps to ensure that just stitching that are done that are high-quality reducing the possibility of item harm during transport.

Safety is a priority that are top it comes to running an case Automatic Bag Stitching Machine, same with the 50 kg automatic packing machine created by JCN. The machine is designed with security features such as crisis stop buttons, security guards, and sensors that detect any intervention that are peoples operation. This ensures that the equipment stops immediately, preventing accidents and injuries.

JCN has been awarded CE certifications ISO 9001:2015 certification. All our products, which have been automatic bag stitching machineand tested before shipping, created completely in factory. Customers are also able inspect the products to confirm that they in compliance with their specifications.

JCN business focuses on production of powder handling equipment and technology.Our main products currently comprise bag dumping, mixing, weighers, automatic bagging robotic palletising systems that is extensively utilized in food, new-material and automatic bag stitching machineindustry, earning company a good reputation.We are company committed to providing professional solutions to our customers through a thorough understanding of their needs.

"JCN focused on R and D of food packaging equipment. have improved and automatic bag stitching machinepackaging machinery technology brought from world. We are 24 hours online assistance, you have any questions about machine operation please feel free get in touch with us."

JCN a manufacturing plant that covers more than 3000 square metres located Nantong, Jiangsu Province. JCN has grown to become one the largest companies that designs engineering, engineers, manufactures automatic bag stitching machinestate-the-art powder handling equipment.

The Automatic Bag Stitching Machine used to stitch bags of various materials, including jute, cotton, paper, and polypropylene, as well as the JCN's jumbo bag packing machine. It is commonly used in industries such as farming, construction, and meals packaging. It is also found in small businesses that require fast and packing that are efficient.

Using an Automatic Bag Stitching Machine is not hard, and anybody can operate it with appropriate training and guidance, the same as automatic packaging supplied by JCN. First, adjust the device towards the bag size and thickness. Then, insert the bag in to the area that are feeding as well as the device will stitch the bag automatically. After the stitching is complete, remove the bag and repeat the process for the bag that are next.

To guarantee the longevity and proper functioning for the Automatic Bag Stitching Machine, regular maintenance is important, along with JCN's product horizontal packing machine. It is vital to obtain the device serviced by a professional to identify any faults and repair them immediately. The grade of the machine also plays a job that are vital it is performance. It is recommended to purchase a machine from a reputable maker to make certain top-notch and performance that are constant.