- Overview

- Inquiry

- Related Products

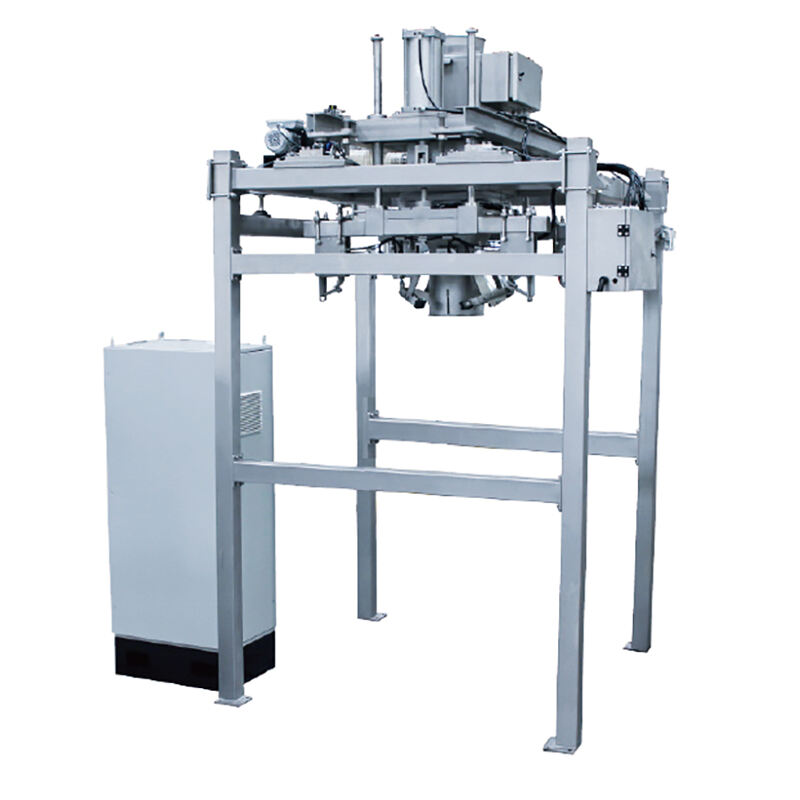

Description:

The bulk bag filler is designed for FIBC bag or jumbo bag or ton bag automatic weighing filling using load cell. Ideal for packaging dry granular,

flakes or powdered materials with very accurate measurements. Thanks to the simple and rugged designs, bulk bag filling machines from JCN

are easy to use and service. This way, it helps to reduce the operation cost to a minimum.

Applications:

All products, ie: coffee beans, animal feed, fertilizer, wheat flour, coffee powder, corn flour, dye powder, food additive powder...

Specifications:

| Model | Weighing range | Accuracy | Speed | Power | Weight | Dimension |

| DCS-1000-ZL-PT | 500-1000KG | ±0.2% |

≤40BPH |

1.0KW | 500KG | 2170*1700*2800MM |

| DCS-1000-ZL-DG |

≤50BPH |

1.5KW | 800KG | 1720*1720*3850MM | ||

| DCS-1000-PD-PT |

≤40BPH |

1.7KW | 620KG | 2170*2100*2700MM | ||

| DCS-1000-PD-DG |

≤50BPH |

2.45KW | 836KG | 1720*2160*3560MM | ||

| DCS-1000-JL-PT |

≤30BPH |

3.8KW | 670KG | 2170*2800*2700MM | ||

| DCS-1000-JL-DG |

≤35BPH |

4.55KW | 886KG | 1720*2800*3450MM | ||

| DCS-1000A-CLX |

≤8BPH |

8.5KW | 1200KG | 1980*1820*5070MM | ||

| DCS-1000C-CLX |

≤4BPH |

11.5KW | 1250KG | 1980*1820*5070MM |

Competitive Advantage:

1. Bag filling weight range: 500-1000kg.

2. Production rate: 1-25bags per hour (depend on the material and filling volume).

3. The touch screen man-machine interface makes the operation convenient and intuitive.

4. Customized suits for different bag sizes.

5. A variety of optional equipment accessories fro various products with different characters.

6. For light powder with high air content, our bottom-up filling (degassing) type bulk bag filler is available.

Case:

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS