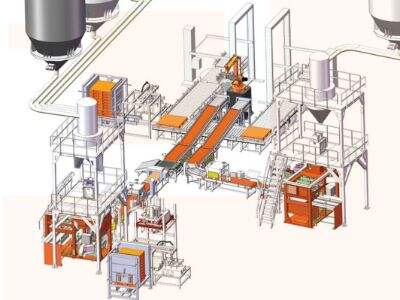

Packaging is one of the key elements that prove helpful in successful business. Catching the eye of consumers requires products to be beautifully packaged. Robotic Palletising systems by JCN are a game changer in the packaging industry for all good reasons, advantages of using Automated Palletiser. These systems are great for gently wrapping delicate items efficiently and in an organized fashion. Robotic Palletising Systems are fully automatic, and unlike manual labor, they work at an impressive pace - both of which help to drive up production efficiency while reducing errors.

Developments

Robotic Palletising Systems prove the ever-changing face of industry by showcasing innovation at the heart of every successful business. Recent developments in Robotic Palletising technology have brought sensors capable of quickly identifying and adapting to the wide range of impediments, packaging styles. By using these sensors, the system could automatically identify which type of object was being educated, not only on weights but also sizes and dimensions, adapting its operation modes. Additionally, these systems are engineered to adapt on-the-fly to any changes that may occur while the barrier compliance packaging operation is in progress.

Safety

The protection of employees is obviously one of the most important issues in any type workplace. Because Automatic Palletizer machine are the ideal and safe solution for packaging tagging products. These systems are completely self-sufficient, which means employees do not have to put themselves at risk when push comes to shove. The system is working to deliver and complete all the packaging processes alone, making it not have room for human errors when there are packing accidents in the workplace. In addition, the system is equipped with safety devices that prevent operation should any kind of intervention occur in the packaging process, ensuring a safe workplace.

Usage

Robotic Palletising Systems are easy to use. Designed for maximum portability, the systems feature a streamlined design that is easy to navigate and includes an intuitive user interface. This moment is fueled by automation that facilitates both, processing and packaging of the products which has eventually made them less dependent on manual labor. Furthermore, Robotic Palletising Systems are easily integrated with other automated systems such as conveyors for a smooth and quick workflow.

Service

To keep the performance of a Robotic Palletising System working to its potential on an ongoing basis, regular maintenance and servicing checks are crucial. This enables a continuous packing process to be carried out without interruption in throughput, simply through planned maintenance. On top of this, most Robotic Palletizer systems will come with a warranty that provides peace of mind in terms of cost and return on investment. In addition, there are 24/7 customer service agents for the answering any questions or concerns that arise throughout using apps.

Conclusion

Summing up, one thing is clear that the future for businesses dealing in massive product packaging belongs to Robotic Palletising Systems. But the exactness, rapidity and safety measures in them are unmatchable so it is totally worth investing which gets pay off in long run. As industries advance, it is becoming increasingly important to keep up with the latest technological developments and there are few revolutions more definitive in this regard than those which apply to Robotic Palletising Systems. Leverage this amazing technology for your business and take it to the next level!

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS