Are you worn out putting this manual labor to stack and carry boxes through your warehouse over and over again? Do you want a quicker and safer way to transact goods? Well, the solution might lie in adapting to future by making use of awesome robotic Palletising systems. This begs the question, what are some of these high-quality robotic Palletising systems by JCN doing so well and how exactly is it affecting our Australian warehousing landscape?

Benefits of Good Quality Robotic Palletising System

Efficient and accurate box-stacking on pallets with a top-tier robotic Palletising system is one of the most prevalent benefits. This not only increases productivity; it also leads to large savings in personnel cost. Additionally, many of the labor-related injuries associated with carrying heavy boxes are eliminated by only having to lift lightweight fillet and portioning containers instead. Also, these systems are essential in avoiding any kind of damage, which might occur to the goods during Palletising.

Robotic Palletizing System - Revolution in Innovation

As evidenced by the recent adoption of technologies like artificial intelligence, machine learning and The Internet Of Things (IoT) in Automated Palletiser today; advancements thanks to technology have brought robotic Palletising systems strides ahead. These advanced features allow robotic systems to learn and adjust in different Palletising scenarios. They also can be used to communicate seamlessly with other machinery and devices along the warehouse floor that increases operational efficiencies and connection between systems.

Robot Palletising Safety Measures

Safety of workers should always be a top priority for any workplace. Top Automatic Palletizer machine include these safety features and operate with sensors that can quickly notice the existence of workers or objects in its surroundings. If such a detection happens, the system immediately stops to avoid any accident or mishap as it takes seriously care of making sure that there are no problems in working environment.

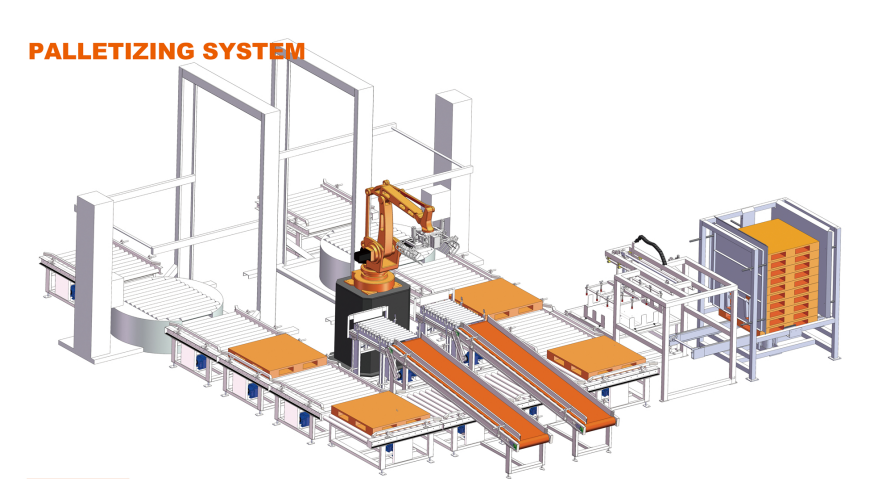

Method of Robotic Palletising System

Robotic Palletising systems actually epitomize what we stand for - adaptable, reliable and robust machinery that are used by food and beverage through to pharmaceutics to automotive even manufacturing plants. Particularly in Palletizing boxes, cartons, bags or trays of different sizes and shapes systems prove their versatility.

Using Robotic Palletising System

The operational ease with which robotic Palletising systems operate is one of its most admirable characteristics. Firstly, the system is programmed with respective Palletising pattern and goods to be pallete. Then you feed the boxes into your Palletizer system, either by conveyor or manually. The robotic arm is then sent to Palletise the boxes in a pre-programed manner before safely returning to end of line where it waits for further commands. When finished, the pallets are lifted with a forklift and sent to its corresponding in delivery per program.

High Quality Robotic Palletising System: Actuators, Drives And Services

These first-class robotic Palletising systems are both built with strong materials and come complete with the latest features available to ensure that your system is durable enough for all of your handling needs. Furthermore, most systems from top manufacturers which take care to ensure customer satisfaction come with an extensive warranty and good after-sales support. Moreover, manufacturers provide training as well as technical support for ensuring a high productivity and best use of the system hence increasing value proposition.

Use of Robotic Palletising From Australia

Robot Palletising systems for various industries in Australia. In the food and drink industry, for example, these systems are used to Palletise boxes with drinks (e. g. cans or bottles) In the automotive sector too, robotic Palletising systems are used to pick up and place heavy car parts on to a pallet. In the pharmaceutical sector these systems have been used to Palletise up boxes of medicines and drugs, indeed other images attest to their museful universal application across a spectrum of industry settings.

In short, good robotic Palletising solutions are now an integral part of any modern warehouse helping to safely and efficiently handle goods as economically feasible. As technology develops, we can expect to see these systems mature so they become easier and simpler ways for a diverse range of industries to handle Palletising processes.

Table of Contents

- Benefits of Good Quality Robotic Palletising System

- Robotic Palletizing System - Revolution in Innovation

- Robot Palletising Safety Measures

- Method of Robotic Palletising System

- Using Robotic Palletising System

- High Quality Robotic Palletising System: Actuators, Drives And Services

- Use of Robotic Palletising From Australia

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

MS

MS